With safety always in mind, we have developed products based beyond industry standards, following our specific Light Bicycle criteria. Before a new product launches, we test for quality, specifically strength and durability. After launch, samples from every production batch are tested to ensure performance consistency, and are part of our quality control inspection checklist.

Standard Testing

The standard or non-destructive testing aims to discover the structural performance of our products without harming their integrity.

Rim Trueness Test

The rim trueness test is our most basic check, and refers to the roundness and flatness of the carbon rim. The lateral and radial movement tolerance for Light Bicycle rims is 0.4mm.

Lateral Stiffness Test

Lateral stiffness testing determines how much a rim resists deformation sideways under a given load. Typically the wider the rim and stiffer it is. Our universal testing machine pushes the rims to measure the deflection.

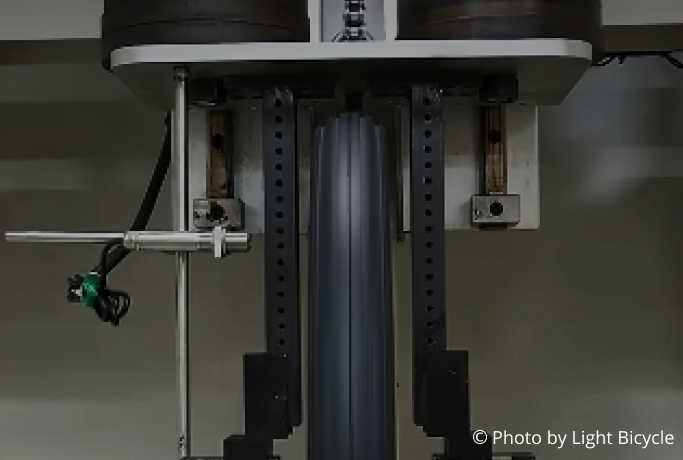

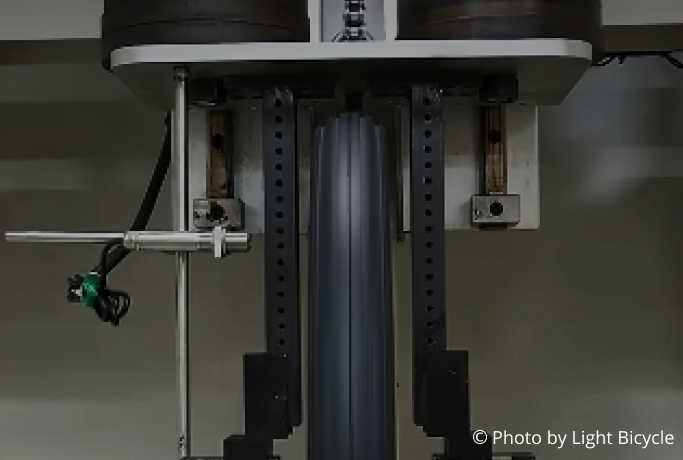

Vertical Stiffness Test

The vertical stiffness test shows how much a rim will compress under load. Weight is slowly applied and we take measurements of the deflection to one hundredth of an inch. Typically, as the rim depth increases the vertical stiffness increases.

Braking Performance Test

Our braking performance test involves stopping distance, peak brake force, and heat dissipation efficiency. Results provide customers with a better idea of the actual braking effects in varied conditions.

Wheel Dynamic Balance Test

Unbalanced wheels and rims are prone to wobble at high speed, which undermines the controllability of the bike and wheels.We test the overall dynamic speed balance of our wheels for smoother rolling efficiency and solid road/tire contact.

Rim Air Leak Test

The rim air leak test is conducted to ensure the airtightness of the rim. This is a critical aspect for tubeless-ready rims, as any air leakage can compromise the tire's performance and lead to pressure loss during rides.

Destructive Testing

Destructive tests allow us to further push and explore the limits of Light Bicycle rims in extreme conditions. It accelerates the development process and helps reduce the risk of damage to our final products.

Spoke Hole Ultimate Strength Test

This test determines that the key area around the holes has been precisely reinforced during the layup process. Holes must endure a force of at least 300kg/f without cracking. The high tension side of a finished wheel is typically built to 120 to 130kg/f as reference.

Impact Resistance Test

The impact resistance test shows the overall structural performance of the wheels, and is performed without tires mounted. The single wheel is fixed on a testing machine base, and a striker (24kg) is dropped from a specific height above. The higher the striker is raised, the greater the impact force.

Wheel Fatigue Test

Our wheel fatigue test is to evaluate the overall durability of a complete wheel system under cycling-like conditions, showing how the wheel performs as a whole.

Greenhouse Test

Our greenhouse test evaluates the thermal durability and structural stability of rims under high-temperature conditions. By simulating extreme heat exposure, this test ensures that rims maintain their integrity and performance even in challenging environments, such as prolonged sun exposure or high-friction braking scenarios.

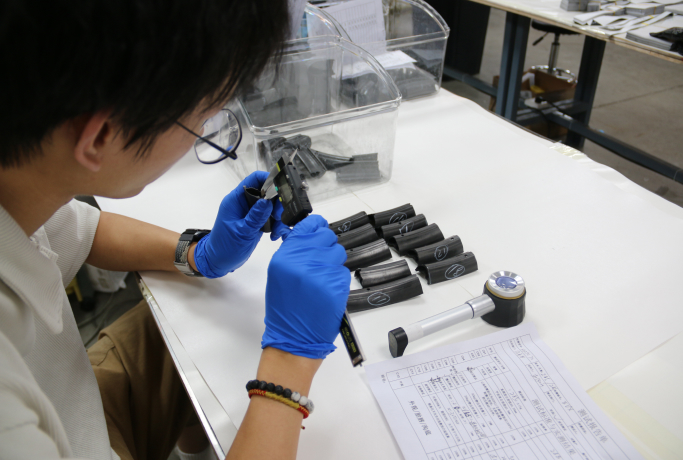

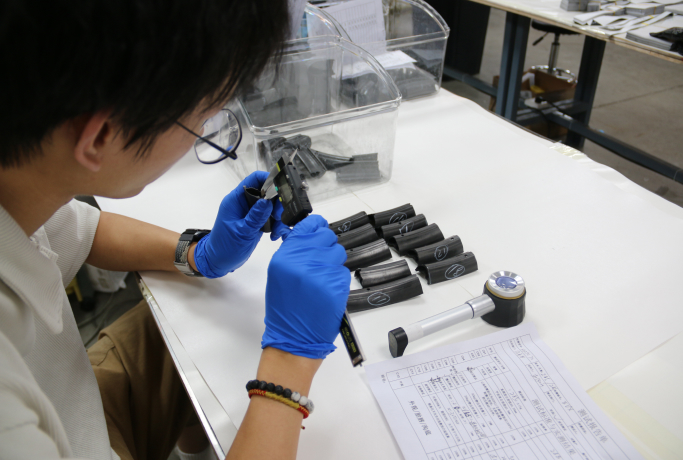

Rim Cutting Pieces Test

The rim cutting pieces test involves analyzing cross-sections of the rim by cutting a portion to evaluate internal and external features. This inspection focuses on identifying any burrs, irregularities, or deviations in dimensional specifications to ensure the rim meets our stringent quality standards.

Fitting Test

We want to understand the overall compatibility of our products with hubs, spokes, nipples, and tires before sending them to ambassadors for long-term tests.

Wheel Building Test

Rim details are amplified during the wheel building process. A rim may look perfect, but if the hole drilling angle is off or if the nipple bed layup isn’t consistent, the wheel will build poorly. Strict Quality Control must be in place along with the manufacturing processes so when it comes time to build, the wheel is predictable and within tight tolerances.

Tire Installation Test

We inspect tire/rim compatibility, the ease of mounting and dismounting the tire, actual tire widths, and brake track deformation due to inflation pressure.

Field Testing

Testing is not complete without skilled riders putting them through their paces. We send our newly developed rims that have passed all the aforementioned tests to riders and ambassadors across the globe. Ali Clarkson, a professional trials rider knows a thing or two about the difference a high quality wheel makes.

Disclaimer

We pick only one sample for every test report and the results will likely vary as the rim diameters change. Please note that the differences between models in test results are specially designed by our engineers for the intended uses.

All the test results of this section are based on the lab criteria of Light Bicycle and are implemented at our well-established testing facilities. Light Bicycle is only responsible for the test results themselves which are not set for any comparison to other brands or such regards.

October 24th, 2020 | Light Bicycle

Get in touch

Feel free to leave a comment if you have any questions or suggestions on our products or other issues.

Please leave your name here.

E-mail is required for further contact.

Please enter a message.

We use cookies for a better experience. Learn more.

Your Cookie Preferences

We use cookies to improve your experience on this website. You may choose which types of cookies to allow and change your preferences at any time. Disabling cookies may impact your experience on this website. You can learn more by viewing our Cookie Policy.

-

Cookies required to enable basic website functionality.

-

Cookies used to understand how the website is being used.

-

Cookies that are used to enhance the functionality of the website.

-

Cookies used to deliver advertising that is more relevant to your interests.

Aceept All Cookies

Save Preferences

Reject All Cookies

Save Preferences

Reject All Cookies

Accept All Cookies